-

aditya@xsun.in -

View Mobile Number - Send SMS

- Send Email

Industrial Lubricants

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Gear Oils, Hydraulic Oils, Open Gear Lubricants, Rust & Oxidations Oils, Slideway Oils and Spindle Oils from Delhi.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Our gear oils are designed to combat the effects of high temperatures, water, contaminants and heavy loads.

Sun chem gear oils are formulated with premium quality extreme pressure additive that is suitable for high loads and protects against wear. They are formulated with anti-foam, anti-rust and anti-wearing properties, they are each designed to ensure excellent performance under heavy and stressful loads and a wide variation of temperatures. These products are available in the iso viscosity grades: 10,15,22,32,46,68,100,150,220,320,460, 680

High-performance gear oil for industrial gearbox applications

Industrial gearboxes are expected to perform under conditions of high heat and heavy loads; and in environments often contaminated with dirt, process debris and water.

Without adequate protection, gears will wear prematurely. You’ll have to replace parts more frequently, change oil more frequently, and worst of all, you’ll experience equipment downtime. To combat difficult conditions, sun chem offers an array of lubricants specially formulated for enclosed industrial gearbox applications.

Three essential attributes when selecting gear oil

Gear oil is made up of two critical components: base oil and additives. Additives impart desirable properties and suppress undesirable ones. The additive package is the backbone of the lubricant’s performance, and a strong backbone will provide the performance and protection you need. When selecting gear oil, there are three essential attributes to consider:

One - The gear oil must remain thermally stable and not oxidize at high temperatures, thus avoiding the creation of sludge or varnish. Keeping the oil from oxidizing will lengthen drain and replacement intervals. As a general rule of thumb, for every 18 degrees f (10 degrees c) increase in fluid temperature above 140°f (60°c), oxidation will reduce the service life of a lubricant by half.

Two – If you have an enclosed gearbox application that is heavily loaded or subject to shock loading, you need gear oil with extreme pressure properties. Gear oil with an ep additive will protect the gear surfaces against extreme pressures.

Three – Gear oil must fight contamination that enters the system, especially water. The oil must be able to demulsify, which allows for easy removal of the water from the gearbox.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Specially formulated hydraulic oils for machine which works on extreme working condition. Sun hydraulic oils, is made up of high quality imported base oil and stabilized with word class antioxidants which keep this oil stable throughout its life. Its viscosity and colour do not change due to thermic cycle. It also work as a very good sealant and protect any leakage, provides a unique lubricant which prevents wear & tear and increase the life of your product.

Hydraulic Lubrication

One of the best ways to ensure smooth-running hydraulic systems is to use the right hydraulic oil and keep it clean and dry. A lubrication reliability effort that includes selecting the right fluid and implementing the correct reliability best practices will protect metal surfaces from wear, leading to improved uptime, reduced maintenance costs, and longer lubricant and equipment life.

hydraulic systems have become more sophisticated in recent years, as speed and pressure have increased tremendously. Because of these changes, wear rates have gone up dramatically and proper selection of hydraulic oil has become much more important.

Identify Suffering Points

Move forward with our proven solutions for extending hydraulic component life.

Contamination

Oil cleanliness is imperative to the reliable operation of hydraulic components. Typical contaminants include dirt, process material, wear debris and water. Contaminated oil leads to problems such as wear, corrosion, accelerated degradation of oil, sluggish operation and component failures.

Solution

Routine filtration is a simple, effective way to extend oil and equipment life. Understanding, achieving and maintaining the right iso cleanliness standard for hydraulic applications can extend the life of the oil by two to three times.

Time-Based Oil Changes

Changing oil on a time-based interval is wasteful and unnecessary. Instead, successful programs incorporate condition-based changes to minimize costs while ensuring efficient hydraulic performance.

Solution

A good oil analysis program is integral to any successful lubricant reliability program. With consistent, accurate monitoring of the condition of your oil, an oil analysis program can help you improve your bottom line with less lubricant to purchase, fewer parts to keep in inventory, less used lubricant requiring disposal, less labor and less downtime.

Underperforming Hydraulic Fluid

Oems typically recommend an iso viscosity grade for hydraulic systems, while other characteristics are often ignored. Hydraulic fluids vary in many key properties, including their thermal and oxidative stability, friction reduction capability, detergency, antifoam characteristics, demulsibility, hydrolytic stability, and ability to maintain viscosity across the temperature range. When any of these properties in a hydraulic fluid are not up to the challenges the equipment and environment pose, they can compound challenges in other areas. Further, some applications or environments have specific requirements, such as fire resistance, food grade, environmental and dielectric strength.

Solution

With both system performance and equipment reliability affected by the lubricant, selecting the right fluid is of utmost importance. Working with a knowledgeable consultant who can help you select and maintain your hydraulic fluid can be the difference between trouble-free operation or continuous problems. Le provides a range of hydraulic fluids for various applications and environments, all of which are engineered to provide the best protection for your equipment.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Large open gears on grinding and pulverizing mills present significant lubrication challenges due to the high-load, heavy-shock nature of the application and constant exposure to harsh environmental conditions, such as cement, limestone, coal or silica dust. Lubrication reliability best practices for open gears include selecting the right lubricant and the right method of application to combat these challenges. Choosing wisely will help protect the gears from wear, increase uptime, and – in most cases – dramatically reduce gear set operating temperatures, lubricant consumption, energy consumption, and waste disposal. This will lead to a cleaner, safer working environment.

We have asphaltic based range of open gear compounds very good tack and load carrying properties.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Brand Name | Sun Chem |

| Application | Industrial Use |

| Shelf Life | 1year |

| Feature | Base Oil, Optimum Quality, Optimum Viscosity |

| Form | Liquid |

Sun Chem brand of Rust and Oxidation inhibited oils are manufactured from highly refined paraffinic base oils. They contain oxidation, corrosion and foam inhibitors. These oils have excellent oxidation stability, corrosion protection and carbon buildup tendency. They come in viscosity ranging from ISO VG 32 to 680 and are recommended for use in turbines of all types where a high-quality, stable lubricant with good water separating characteristics are required.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

Coming in a wide range of iso grades our slide and way oils lubricant designed to lubricate machine tool slides, tables and feed mechanisms. with excellent frictional properties, slide way adhesion and anti-wear performance, our slide and way oils provide efficient machining accuracy and reliable protection for your equipment.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

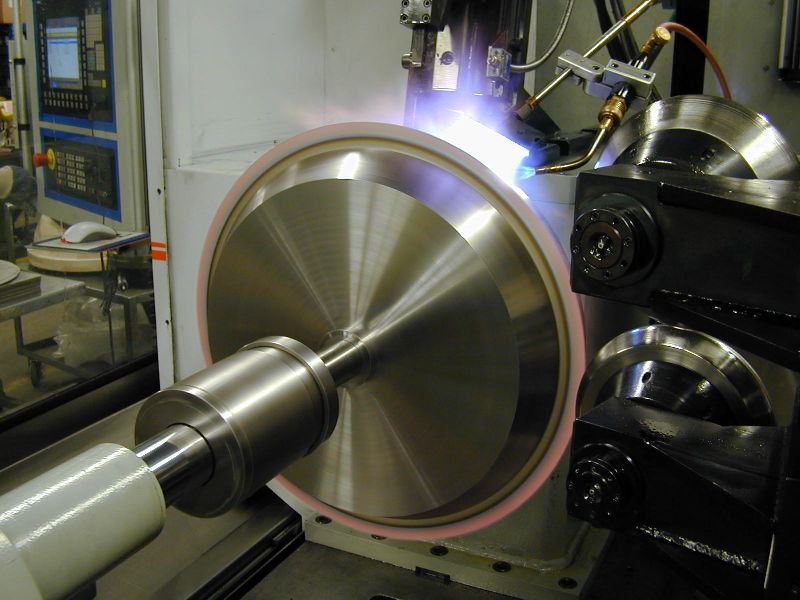

Sun Chem brand of Spindle oils are low-viscosity, Ultra pure, Aromatic and VOC free oils designed for the lubrication of very high-speed spindles in industrial machinery and machine tools. These oils are compounded to give excellent resistance to wear, varnish build-up and rust formation, available in ISO VG 2, 10, 15 and 22.

A recent survey resulted in the following analysis of the causes of spindle malfunctions: 42% wear on spindle bearings, 33% collisions, 15% other and 5% each due to dirt and lubrication. While many users are aware of the key importance of the spindle system, few take full advantage of the available room for optimization, especially considering that the investment in a high-frequency spindle averages 10–15% of the cost of the entire machine. Sun Chem Spindle Line creates an ideal environment for reducing spindle malfunctions and enhancing process reliability.

At 40,000 rpm, even the tiniest dirt particle can have a devastating impact on a spindle’s service life. At Sun Chem our product stands for ultra pure quality.

SPINDLE CLEANING Thorough cleaning of the system is recommended every time the spindle coolant is changed (either during maintenance or when switching spindle coolant). The ideal conditions for a smoothly functioning cooling system only exist after cleaning.